Frequently Asked Questions

Gutter Pumper Frequently Asked Questions

A. Gutter Pumper is made from U.V. resistant ASA; a tough recyclable plastic that has superior resistance to outdoor exposure and ageing.

A. A 32 mm hole is drilled in a flat bottom eaves gutter. The Gutter Pumper is fitted into the hole, connected to 20mm PVC pressure pipe and fittings then plumbed to a legal point of discharge. In some Australian States, this is allowable DIY work but check your State’s regulations.

A. Paved areas, decking, paths and garden beds often make fitting another downpipe difficult and expensive. A painted 20 mm PVC pressure pipe is less obtrusive in many areas than a downpipe.

A. It is best to occasionally check for any larger debris. Debris is usually flushed past the Gutter Pumper during heavy rain before the syphonic action starts.

A. The BCA requires inverted nozzles to be fitted at the gutter’s high point to avoid damming.

A. Gutter Pumper should be fitted near gutter’s high point as stated in our fitting instructions.

Most overflows occur near a gutter’s high point as explained at GUTTERS OVERFLOW.

Unless there is a heavy build up of debris, leaves wash from the high point during heavy rain prior to the Gutter Pumper generating a vacuum.

Gutter Pumper generates a vacuum only after water rises above the anti vortex baffle, a minimum water depth of 25mm. Prior to this, Gutter Pumper drains slowly by gravity weir flow once the water level is approximately 5 mm deep. For a small leaf to enter the outlet during weir flow, the leaf would need to do a 90 degree turn against the flow. Small leaves sucked into the Gutter Pumper during full flow are quickly dispersed.

Gutter Pumper operates with vacuum breaks whenever the water level drops below the baffle. When the vacuum stops, Gutter Pumper resumes weir flow and the water, being turbulent due to the heavy rain, swiftly flows past, flushing debris along the way.

When fitting Gutter Pumper near a roof valley or if accumulated debris is a problem, AQUATREK recommends that a suitable leaf barrier is fitted.

A. If the existing downpipe and pop are inadequate, the water will overflow at the downpipe. Because your gutter overflows away from the downpipe, there is little chance that fitting a bigger downpipe and pop will solve the problem. Gutters overflowing near a high point are common and fitting a Gutter Pumper near the high point attacks the problem at its source.

Rainheads need to be fitted to the gutter and not in the downpipe if they are to improve the drainage. We also see larger downpipes fitted to their original pops. This does not improve drainage as drainage is determined by pop size, no matter how large the downpipe is.

A. Slab movement and settling can alter a gutter’s slope. The best precaution is to install gutters on new homes with more slope than the required minimum. This often requires no more than one extra downpipe.

Regardless of this, water pooling in a gutter up to a depth of 10 mm for three days is deemed acceptable!

Is this correct?

A. The “12 metre rule” is a BCA regulation.

The spacing between downpipes must not be more than 12 m.

This was revised on the 1st of May, 2007 to state:

“3.5.2.5 Downpipes - size and installation Downpipes must - (a) not serve more than 12m of gutter length for each downpipe;

When the BCA was revised on 1st May 2013, it again stated:

The spacing between downpipes must not be more than 12m.

Q. We live in QLD and our gutters always overflow. Can Gutter Pumper cope with heavy QLD downpours?

A. Gutter Pumper has been successfully tested in every Australian State, including Qld. 1 mm of rain on 1 square metre = 1 litre. When harvesting a 30 square metre roof catchment area, a Gutter Pumper can divert up to 2 mm of rainfall per minute. This is huge!

Q. Can we use Gutter Pumper to harvest rainwater as well as stopping overflows?

A. Yes, many people do this. Because of the shorter hydraulic head, it is best to use a 25mm X 20mm PVC reducing elbow to connect the 20 mm vertical drop to a 25 mm horizontal pipe when diverting water to the tank’s top meshed inlet. For quality rainwater harvesting, also consider connecting a Supadiverta to every downpipe.

Will my steel gutters rust if I drill holes in them?

No - and here are the reasons why they won’t.

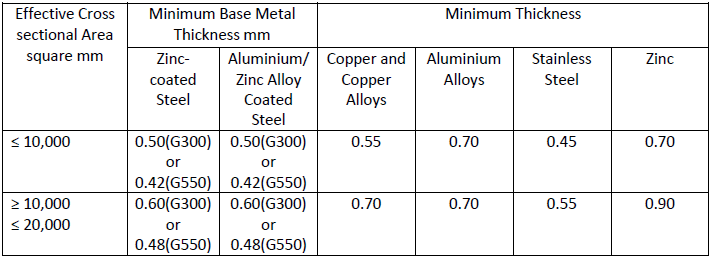

Many types of material are used in modern gutters but by far the most common are the zinc/aluminium coated steel type. Probably 90% of the gutters now supplied are of this material and they can be either coloured or the original Zinalume finish. Below is a small table of the types of metal, the thickness required and the minimum cross sectional areas used in the gutters supplied today.

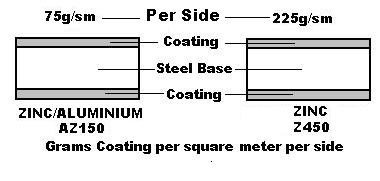

Let’s make this simple and just explain some of the terms of metal used in gutters. It would only be in very exceptional circumstances that the last four would be installed as guttering on a normal house. So now we are down to two types: ZINC Coated and ZINC/ALUMINIUM Coated – fairly simple as this is the coating over bare steel (which will rust). The diagram below shows roughly the base steel (which is the Base Metal Thickness or BMT) and the coating which is sometimes recorded as AZ or Z which simply means coated by an Aluminium/Zinc alloy or just Zinc by itself.

Most gutters supplied today are of the type covered in a Zinc/Aluminium coating over the base steel which normally would be about 0.42mm thick as in the left hand sketch above. The two coatings above are normally Zinc or Zinc/Aluminium and can be applied in three ways from as a thin layer of electroplated Zinc, a heavy layer of Zinc applied by hot-dripping (galvanized) or the technologically advanced zinc/aluminium alloy. Don’t worry too much as your gutter has a 95% chance of being of the last type of a Zinc/Aluminium alloy coated metal gutter. To explain why this is the normal practice – Zinc/Aluminium Alloy coated steel lasts up to four times longer than Zinc coated steel of the same thickness.

This Zinc/Aluminium coating serves two purposes –

1. By providing a physical barrier between the atmosphere and the steel

2. By giving a galvanic action

Painted bare steel if scratched or drilled will rust as the bare metal is exposed to the atmosphere as paint alone will not instigate a galvanic reaction. The Zinc/Aluminium coated steel if cut, scratched or drilled does not allow the steel to rust by a simple fact that the coating sacrifices itself to coat the steel from exposure to the atmosphere. So when a drill cuts a hole in the gutter, bare steel is exposed but this is quickly coated by the Zinc/Aluminium on the top and bottom surfaces through a galvanic reaction with moisture which builds up a protective Zinc coating over the exposed metal.

Galvanic reaction also protects the original downpipe drops when they are drilled or cut into the gutter. It is also exactly the same with roofing sheets that have all four edges initially exposed, moisture provides the electrolyte that completes the galvanic reaction that soon seals up the base metal surface.

The most important aspect of roofing and gutting when considering coating is the compatibility of metals. There are many tables available that show which ones should not be used together. For example – you cannot use a Zinc/Aluminium coated roof that drains into a Galvanised (Zinc only) gutter. The colour bonded gutters are exactly the same – they have the Zinc/Aluminium coating under the paint layer and will behave exactly as the Zinc/Aluminium coated material.

SO A GUTTER THAT YOU DRILL A HOLE INTO WILL NOT RUST IF IT IS ZINC OR ZINC/ALUMINIUM COATED!